Mt Henry Bridge Widening - 2012 Booklet

Mt Henry Bridge Widening and Strengthening (2004 – 2006)

To accommodate the suburban railway line to Mandurah the bridge was widened and strengthened between 2004 and 2006. The tender documents called for a symmetrical widening of the existing bridge. However the successful tenderer, Leighton Contractors, with their design consultants, Wyche Consultants, GHD and Coffey Geosciences, proposed a completely independent bridge on the western side and fitting into the existing bridge. The north bound roadway would be carried by the new bridge and the south bound roadway carried by the existing bridge. The railway formation was to be supported by the strengthening of the existing bridge.

Due to restrictions on land availability the new bridge had to fit into the existing one with the new deck overhanging the old one. The new bridge east top cantilever clears the old kerb by a minimum of 85 mm and the vertical gap between the lower cantilevers of the two bridges is approximately 185 mm.

Incremental launching

Leighton Contractors used the incremental launching method for putting the bridge superstructure in place. Due to the 76 metre spans temporary mid span piers had to be used to support the launching nose (which was one used at the Narrows site in 1999 – 2001, albeit with some modifications) and the forward end of the concrete beam. The use of temporary piers also gave the construction team tighter control over displacements during launching which was critical in ensuring the new bridge did not contact the old bridge during the construction phase. The design and construction of the temporary piers provided a major challenge for the design and construction team. Tubular steel piles, similar to those used for the permanent piers, were used. The designers were concerned that the upper soft alluvium layer of the river bed would provide little lateral restraint to the piles.

A solution was developed whereby the temporary pier pile caps were connected to the existing bridge in the transverse direction by a flexible prop system capable of accommodating longitudinal movements. Longitudinal connection was achieved by running prestressing cables between the temporary and permanent piers such that each temporary pier was tied to adjacent permanent piers. This bracing system permitted each temporary pier to be supported by only four piles. Extensive monitoring of the movements of each temporary pier during stressing of the bracing cables enabled revisions of the stressing sequence to achieve an optimum result. Results confirmed that the geotechnical engineer’s estimate of the lateral soil stiffness values were conservative.

Deck construction and prestress

Leighton Contractors opted to launch the superstructure in 25.4 metre lengths, approximately one third of the main span lengths. To speed up construction they established a two segment casting bed, whereby in the rear bed the bottom flange and webs were monolithically cast, and simultaneously in the front bed the top flanges were cast. In addition launching prestress operations were minimised by running each concentric prestress cable for three segment lengths (equal to one main span length of 76 metres). Hence for the construction of each segment only one third of the concentric prestress had to be applied.

The efficient design of the temporary piers, the two part construction staging of the deck, and the concentric prestress arrangement all contributed to the speedy construction of the duplicate Mt Henry Bridge, which was opened to traffic two years after the design and construct contract was let.

Author:

Don Young 2020

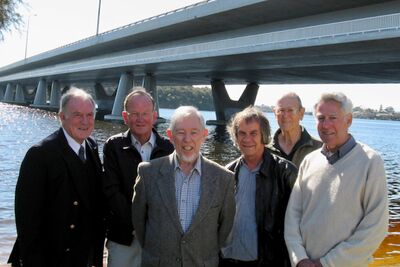

Wyche Consulting

In 2004 Wyche Consulting were engaged in the strengthening works to the original Mount Henry Bridge to carry increased vehicle and rail loading and the design of the new 660m long, incrementally launched, single cell concrete box girder bridge duplication. Joe Wyche has made available a copy of his presentation on this project as well as a paper on the incremental launching challenges. A copy of the April 2007 presentation by Joe Wyche titled 'Constructing the New Mt Henry Bridge, and Strengthening the Old Mt Henry Bridge' is available here. A copy of the paper by Noel Wenham from Wyche Consulting titled 'Incremental Launching Challenges on Mount Henry Bridge' is available here.